How does co-packing work?

What is a co-pack agreement? Co-packing is an agreement between a firm A and its co-packer, firm B. It allows firm B to handle all the packaging processes for firm A.

This contract allows firm A to focus on its specialty, which is production, and firm B focuses on the packaging, branding, and logistics. The two companies have to come to a formal co-packing agreement which outlines the nature of their relationship.

Why do firms opt for co-packing?

- Cost – For most firms that opt to enter into a co-packing agreement, cost is the main driving factor. Instead of firm A establishing a packaging unit, these costs can be saved by outsourcing the services of a co-packer.

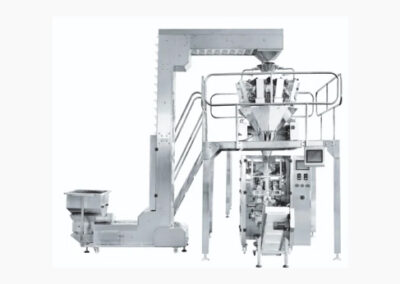

- Technology – Co-packers invest a lot of resources in technology that helps to make the packing exercise smooth and time efficient. Many companies lack this technology, so it is necessary to seek a partnership with a co-packer.

- Spike in demand – A co packer’s services can come in handy if a company is experiencing a spike in demand for its products. This sudden increase may mean the company is unable to meet the packaging requirements at its facility, so they need to enter into an agreement with a co-packer.

- Specialization – Specialization is a core principle of economics and running a business. Companies that choose to specialize in one specific task might find the services of a co-packer to be necessary. This may inform their choice to enter into a co-packing agreement.

Which industries can co-packing serve?

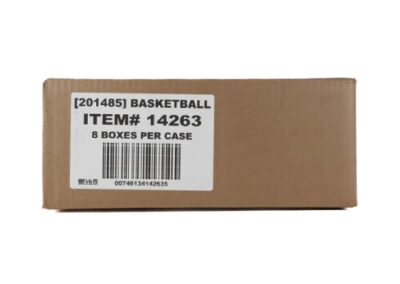

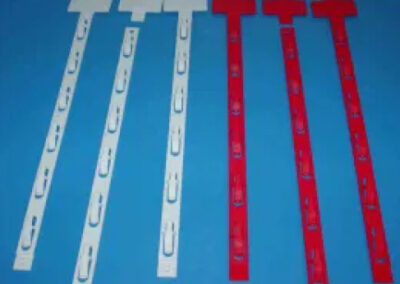

Co-packing, as has been established, focuses on the packaging and branding of products given to them with permission from another company. The services of a co-packer can cut across many industries.

With the question of what co-packing is and how it works answered, the following list of industries stand to benefit most from agreements with a co-packer.

Kitting

Display-building

Labelling

Addition of give-aways

Tray Building

Wrapping

Re-packing

Re-packing

(Thermo)Shrinking

(Thermo)Shrinking